Advanced Composite Manufacturing

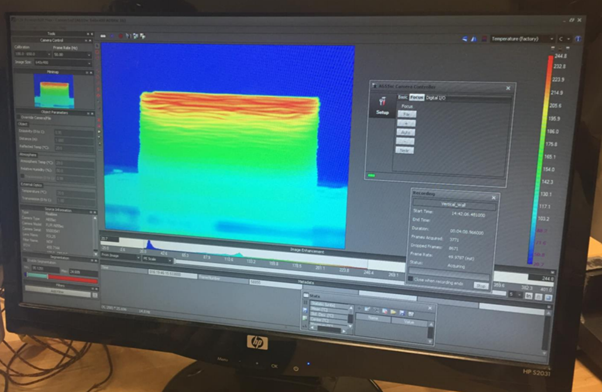

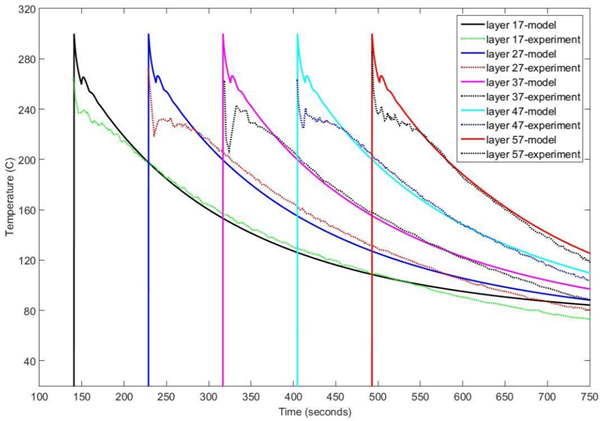

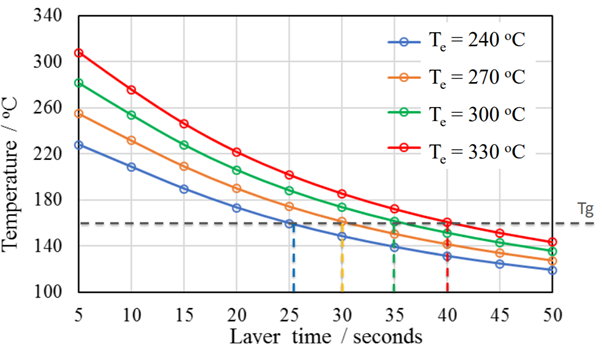

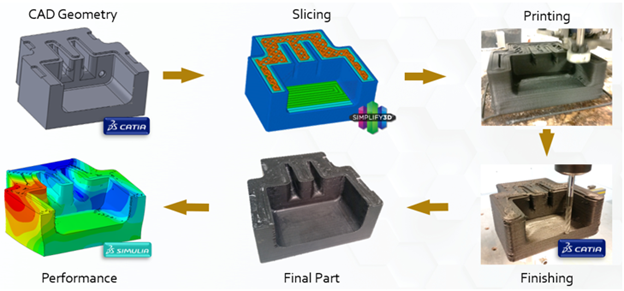

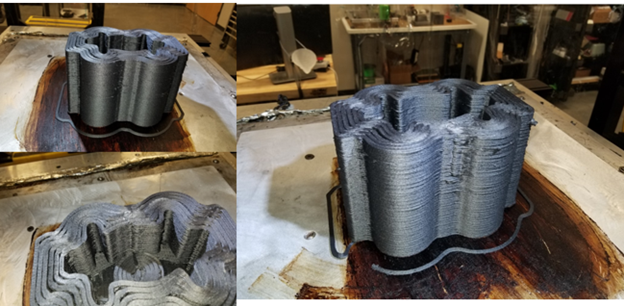

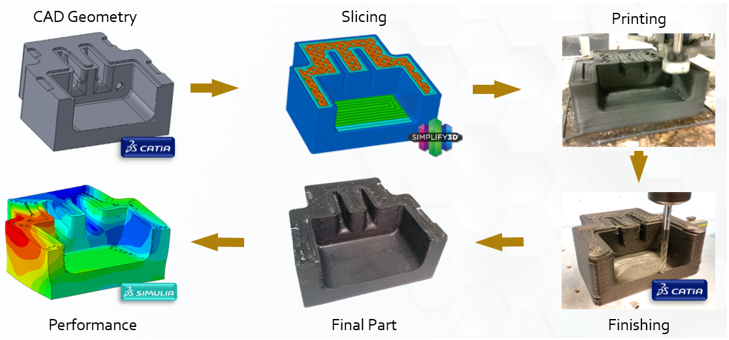

Abstract: As part of the project-based course taught by Prof. R. Byron Pipes at Purdue University, this experience aimed at examining the phenomenon involved in manufacturing of advanced composites, such as Extrusion Deposition Additive Manufacturing (EDAM), Darcy flow, permeability and compaction of fiber beds, thermoset reaction kinetics, polymer viscosity, property measurements, heat transfer, void formation, polymer physical properties, anisotropic composite properties, and residual behavior. The course developed the following theoretical and experimental skills”

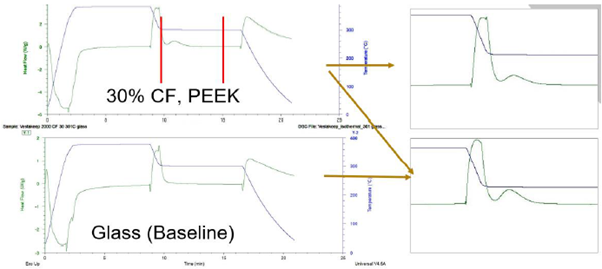

- Polymer Transitions (Glass transition temp, degree of cure, visco-elastic behavior)

- Cure Kinetics and Rheology

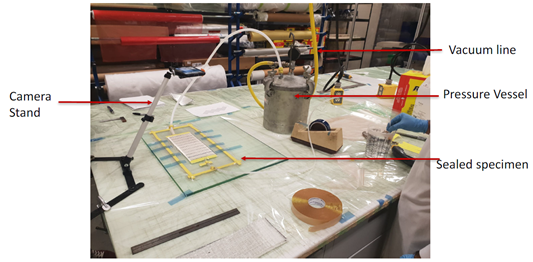

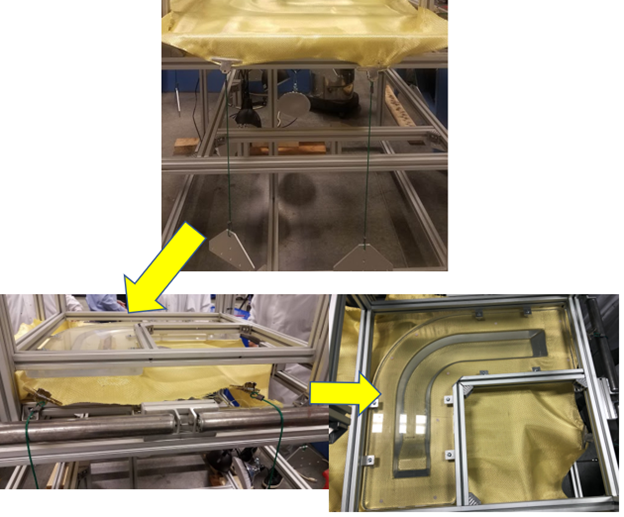

- Darcy’s Law

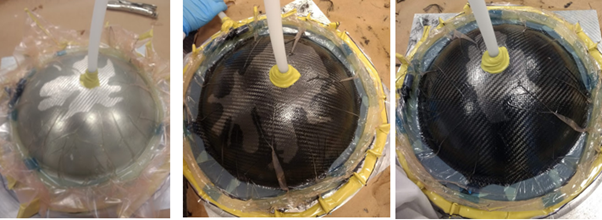

- In and out of autoclave manufacturing (VARTM, Oven, Autoclave)

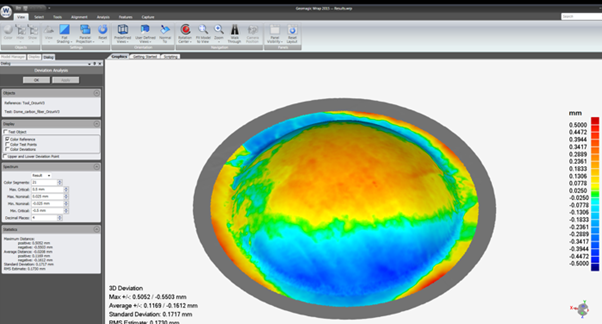

- Thermal residual stresses and deformation

- Percolation and transverse squeeze flow

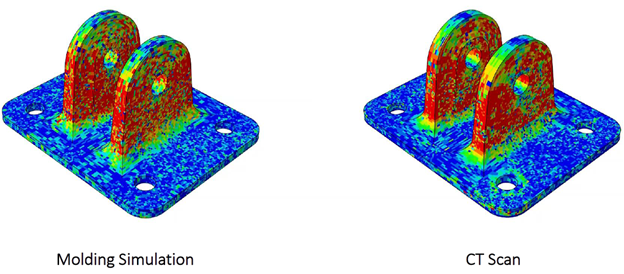

- Compression molding