COMPACT MUON SOLENOID (CMS) – CERN

Position: Composites Research and Characterization Engineer

Manager: Dr. Benjamin Denos

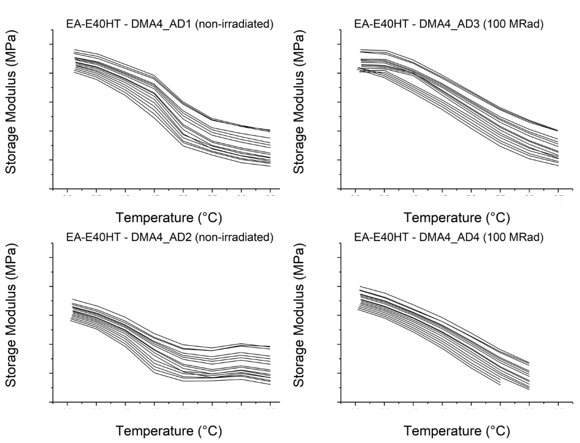

Abstract: Purdue’s Composites Manufacturing and Simulation Center (CMSC) is designing and manufacturing carbon fiber reinforced polymer (CFRP) composite structures for the Inner Tracker Upgrade of the Compact Muon Solenoid (CMS) at CERN. The structural adhesives and CFRP materials used in the design must maintain stiffness within the operating temperature range of -35°C to 30°C when subject to high radiation doses. The structures will support silicon detectors and services for particle collision experiments. Adhesives and CFRP materials closest to the proton-proton interactions will experience high amounts of gamma radiation.

Brief Summary

- Design and optimize Inner Tracking System service cylinder and prototype using CFRP

- Perform hand-layup and autoclave curing of 3m to 6m long prototype

- Laser scan and perform FEA analysis using ABAQUS

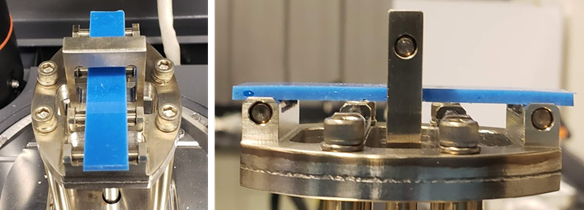

- Characterize radiated samples via tensile response, DMA results and CTE analysis