IACMI 7.8 CO-MOLDING

Position: Composites Research and Characterization Engineer

Manager: Dr. Benjamin Denos

Abstract: Volkswagen and IDI Composites led a research project to create a prototype liftgate through sheet molding

compound. As part of Purdue’s Composite Manufacturing and Simulation Center, I was primarily responsible for the

project’s large-scale material characterization and aiding with design and material flow simulation. During the course

of this industry-driven project, I performed a wide range of material characterization tests at different temperatures,

along with their data analyses. I lead the operational process workflow of sample design, manufacturing, testing,

characterization as well as data analysis and reporting of results.

Brief Summary

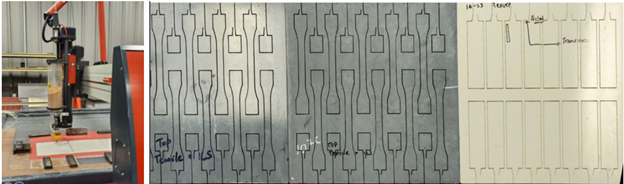

- Designed and manufactured over 500 test specimens from various Sheet Molded Compound (SMC) Glass-Fiber composite plates prepared by IDI Composites

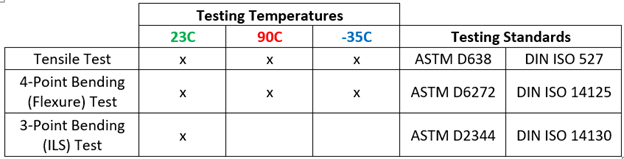

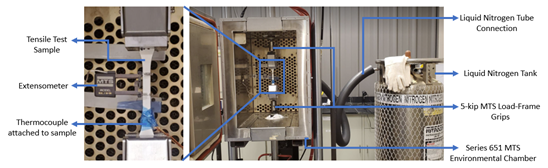

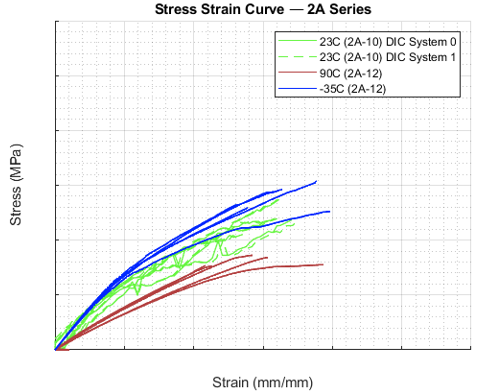

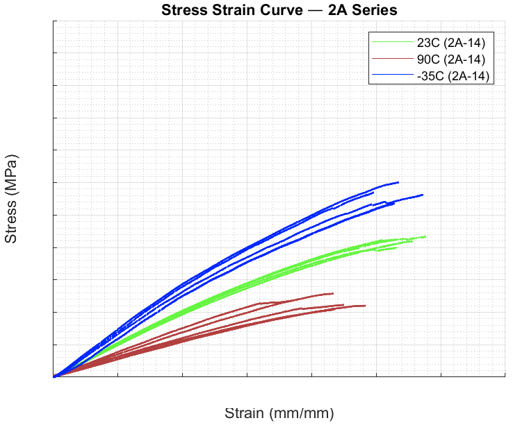

- Tested samples under tensile and 4-point loading at ambient, 90°C and -35°C temperatures and 3-point loading at ambient temperature

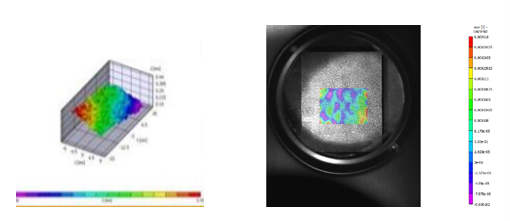

- Carried out Digital Imaging Correlation (DIC) to retrieve stress-strain, load-displacement, heat transfer and fracture data and Vic-3D software

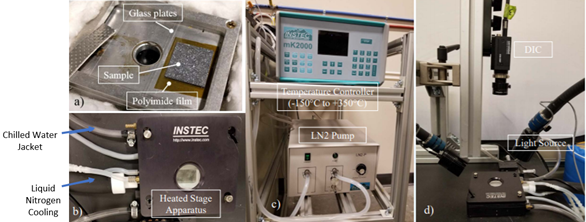

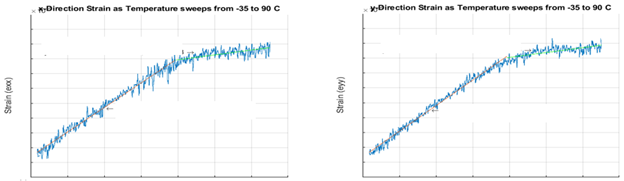

- Performed Coefficient of Thermal Expansion (CTE) testing of samples using a similar DIC mechanism

- Performed data analysis and visualization with the help of MATLAB software - created global testing and characterization MATLAB code to carry out analysis with reduced downtime and efficient user-customization

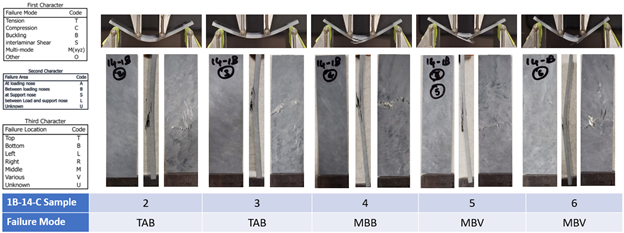

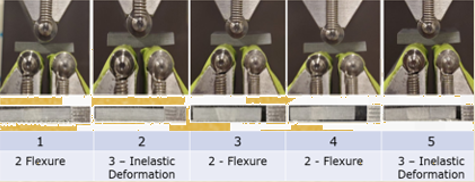

- Documented failure modes of tested samples through failure analysis

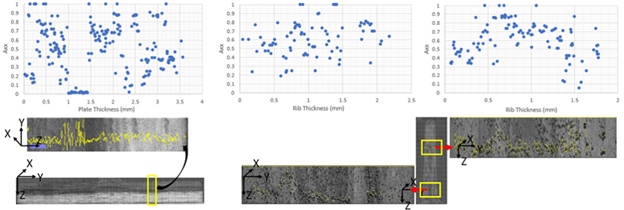

- Performed optical microscopy of sample cross-sections to measure fiber orientation to study manufacturing effects on material flow

- Aided with material flow and finite element simulation with the help of ABAQUS, utilizing the Smoothed Particle Hydrodynamics (SPH) feature

Project Images

Figure 1. ASTM and ISO Standards used for Specimen Manufacturing, Testing and Data Post-Processing at Various Temperatures

Figure 2. Specimen Manufacturing using Water-Jet Cutter

Figure 3. 23°C Tensile Test DIC Mechanism Set-Up

Figure 4. 4-Point Bending (Flexure) Tests and failure Mode Analysis of Samples

Figure 5. 3-Point Bending (Interlaminar Shear) Tests and failure Mode Analysis of Samples

Figure 6. 90°C and -35°C Tensile Test Environmental Chamber and Extensometer Set-Up

Figure 7. Coefficient of Thermal Expansion (CTE) Analysis Experimental Set-Up

Figure 8. DIC Analyses

Figure 9. X and Y direction strain from the CTE test

Figure 10. Tensile Stress-Strain Curve

Figure 11. Flexure Stress-Strain Curve

Figure 12. Microscopy Fiber Ellipse ROI and Inspection