SOLIDWORKS SIMULATION PROJECTS

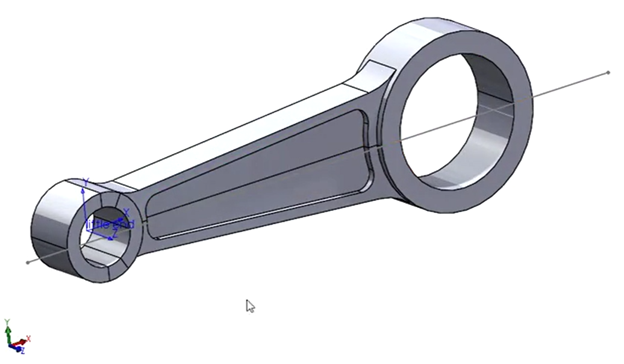

Abstract: In this multi-part project-based course conducted by Toney Abbey and Gabriel Corbett, I studied modern CAD and powerful analysis and simulation using finite element analysis. The primary tool for design and analysis for this project was SolidWorks. I designed and analyzed several simple and complex parts as well as assemblies throughout the course of this project. Following are the three main categories that the project was split into. A certificate was awarded at the end of each category.

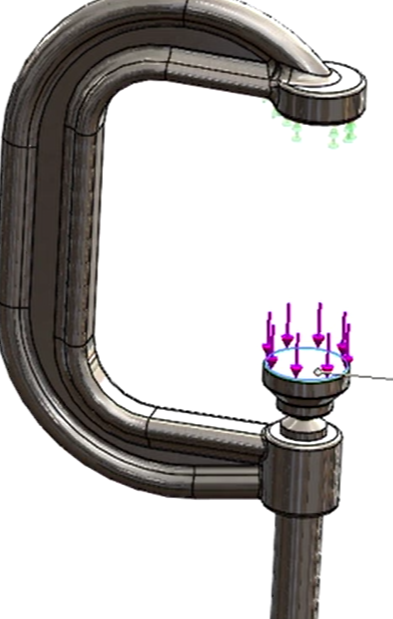

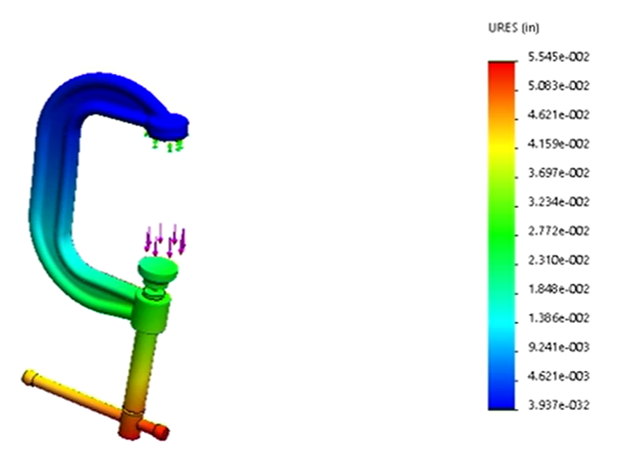

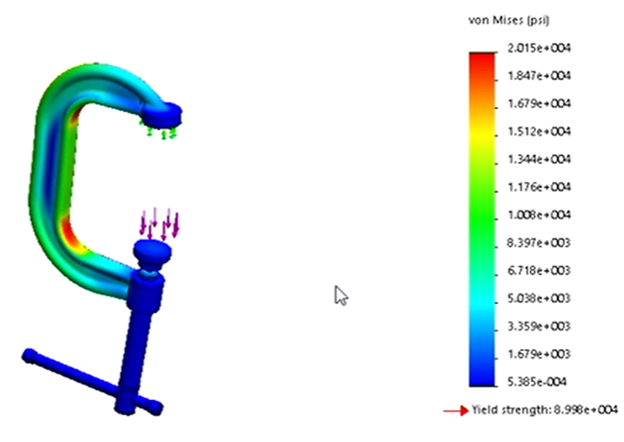

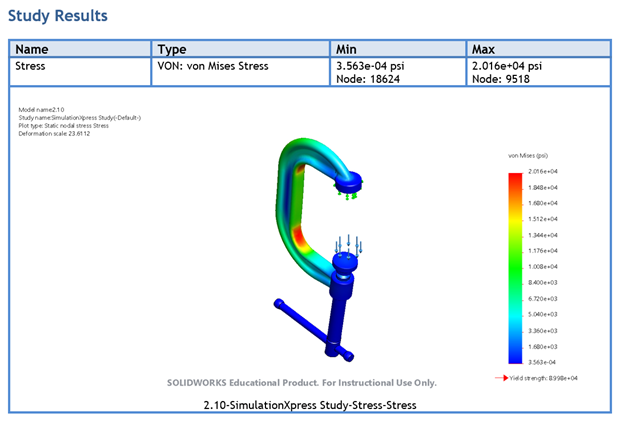

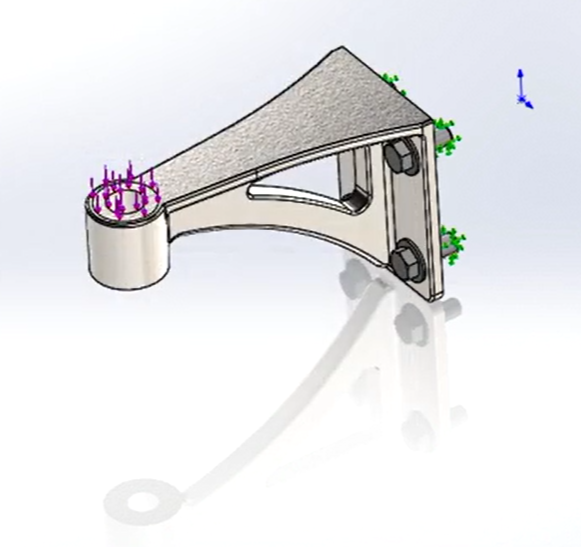

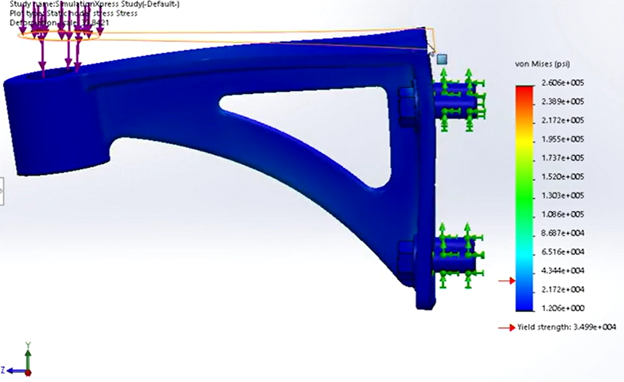

I. SIMULATION XPRESS

Introduction to SimulationXpress by learning both the basics of simulation and advanced model preparation steps. This category showed how to create and run simulations so you can evaluate the function and strength of your models, including identifying which parts of your designs need additional modifications — using stress testing, displacement values, and factor of safety results. Here, we see how to apply improvements and reassess the iterations you make to ultimately ensure your works are solid.

Learning Objectives

- Simulation workflows and options

- Xpress vs. Simulation vs. Sim pro

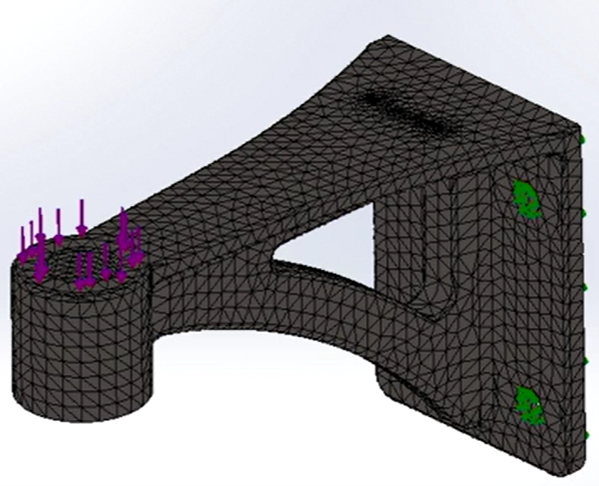

- Fixtures, loads, materials, and mesh

- Running a simulation

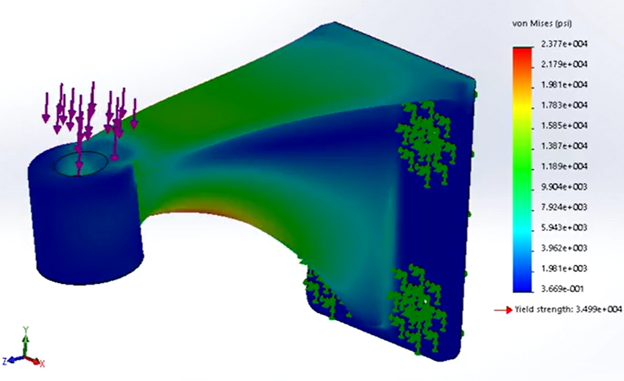

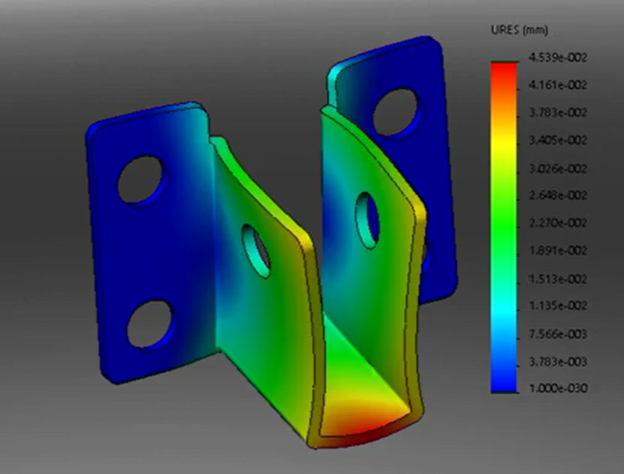

- Reviewing stress, displacement, and factor of safety

- Updating and iterating

- Producing reports

- Model preparation

- Simulating multiple parts

- Importing assemblies as parts

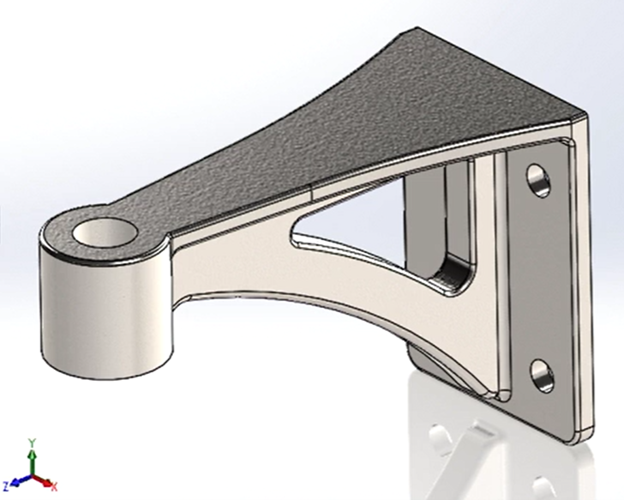

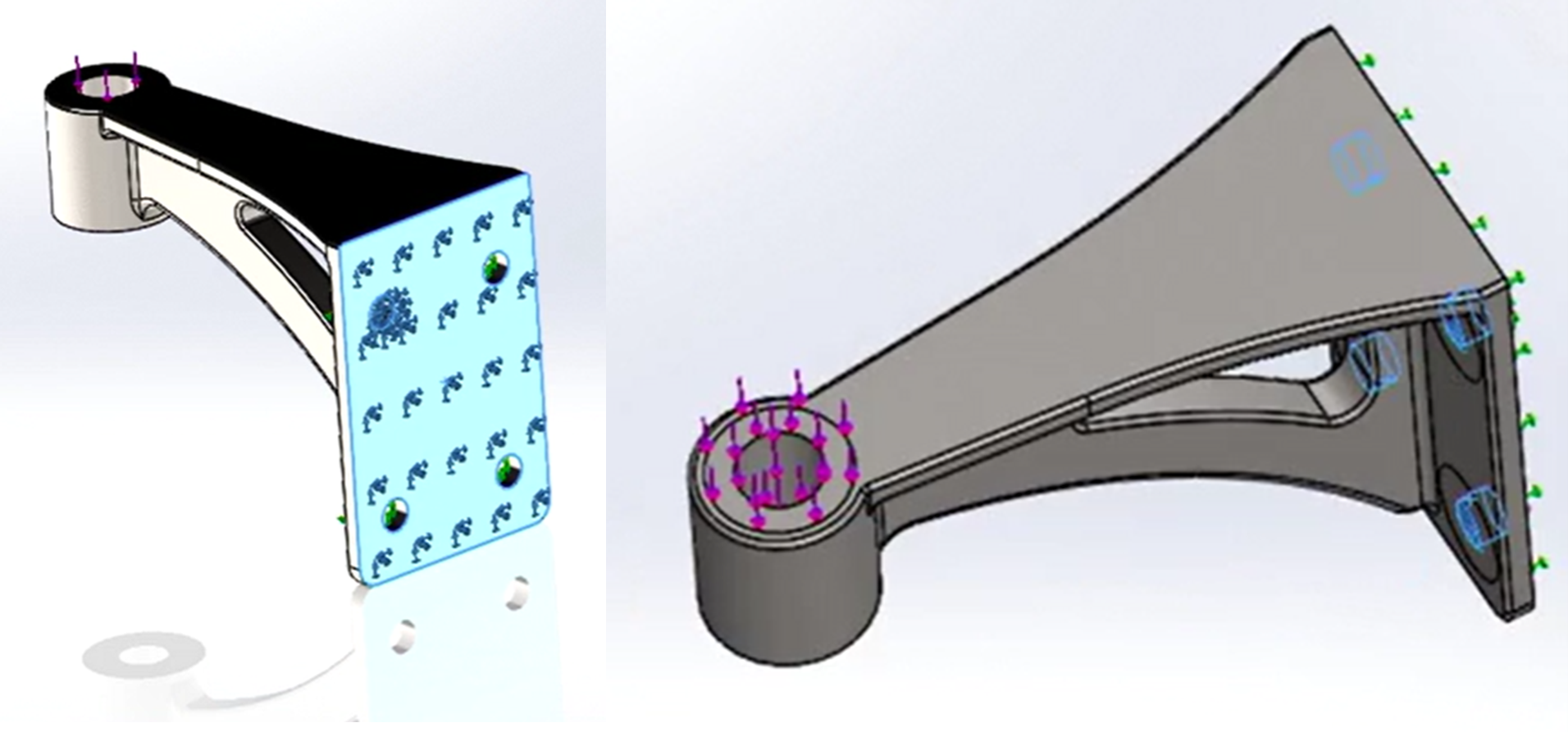

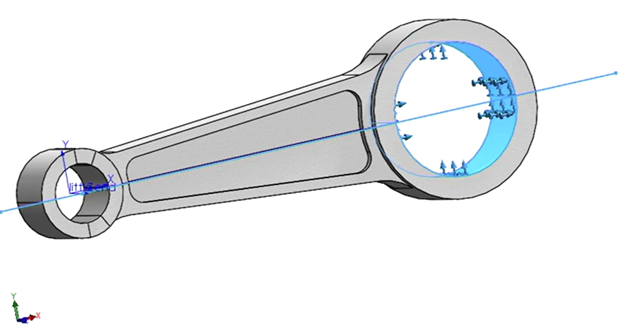

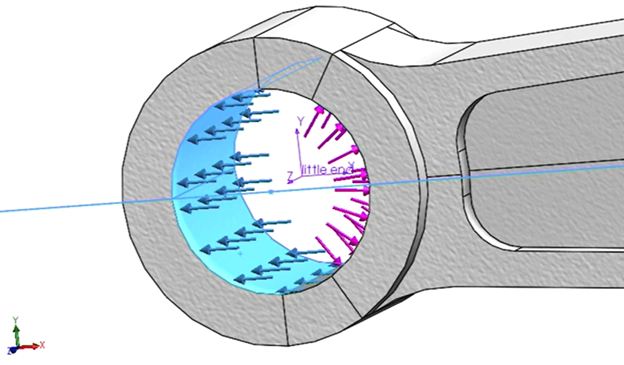

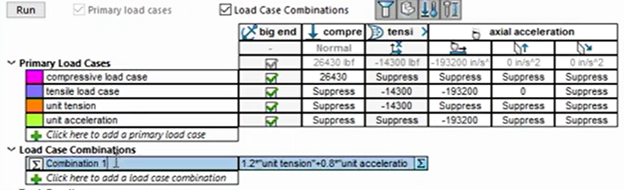

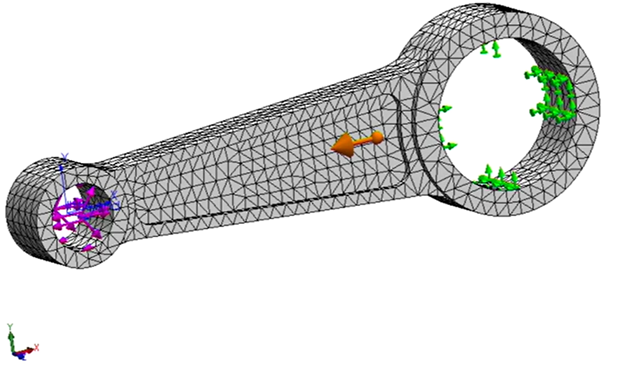

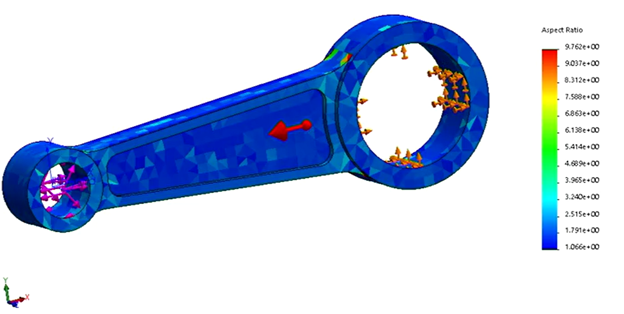

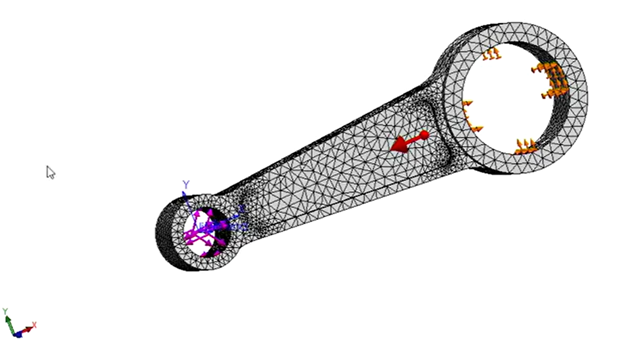

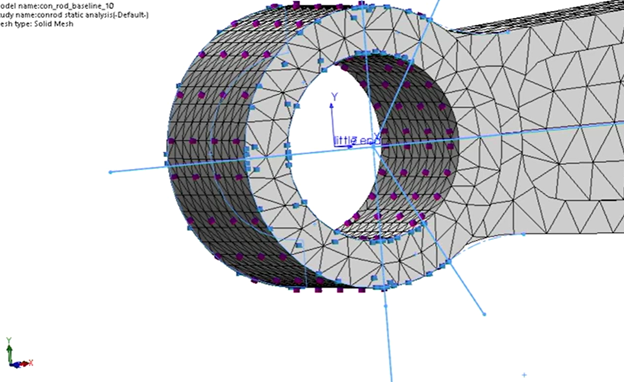

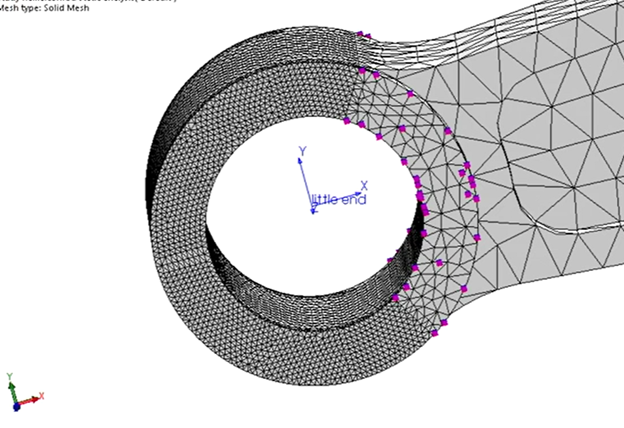

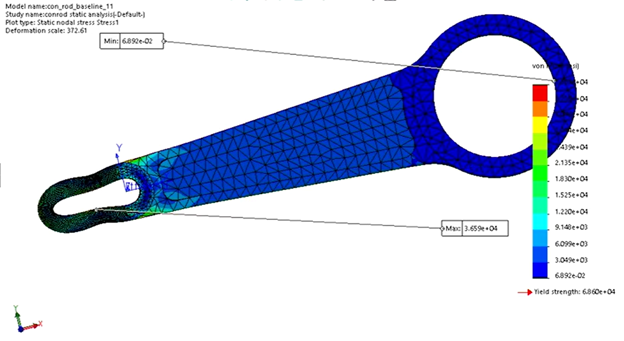

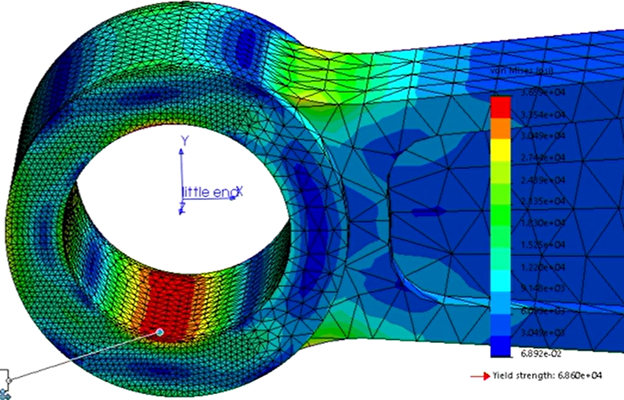

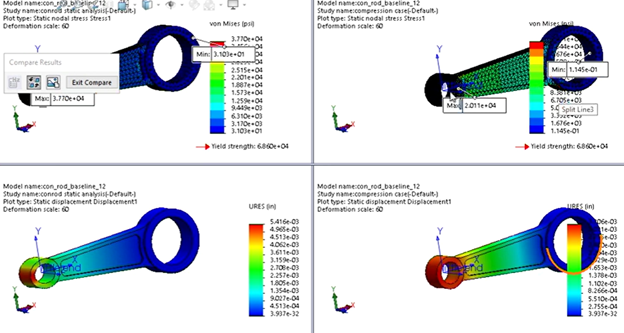

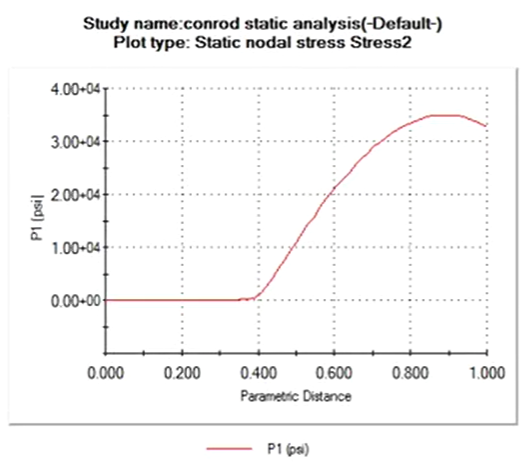

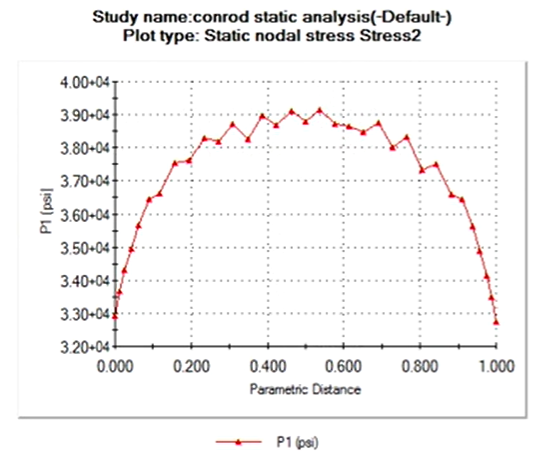

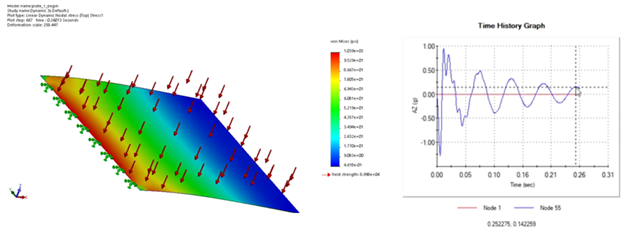

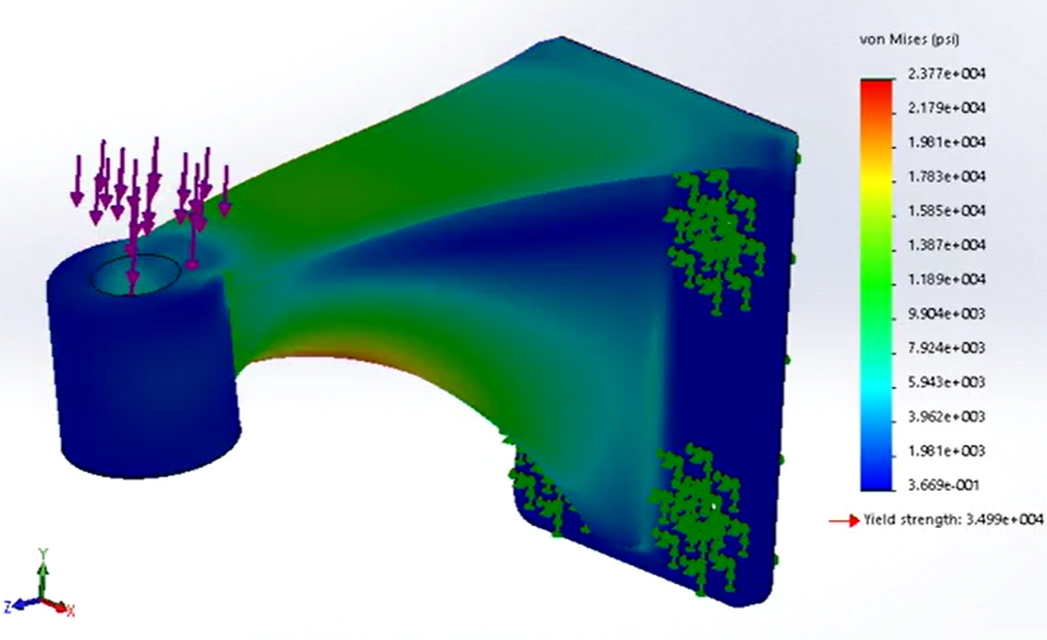

II. STRUCTURAL ANALYSIS

SOLIDWORKS Simulation offers tools that can help you test your designs and determine how to best enhance the quality of your products. In order to perform effective stress analysis, designers need to know not only the SOLIDWORKS Simulation user interface, but also the methodology and application of finite element analysis (FEA) in general. This course introduces how to set up a model for FEA analysis, run the analysis, and interpret the results to optimize your SOLIDWORKS models. Upon completing this course, you'll have the knowledge you need to carry out FEA with confidence.

Learning Objectives

- Setting up Simulation properties and defined views

- Preparing the geometry

- Setting up a local coordinate system

- Splitting surfaces

- Defining the constraint and the loads

- Meshing

- Running analysis

- Contour control

- Y plots

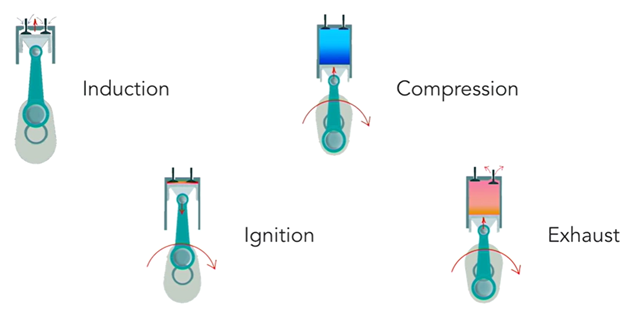

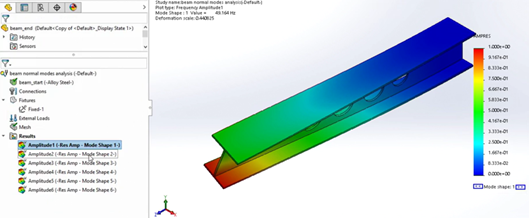

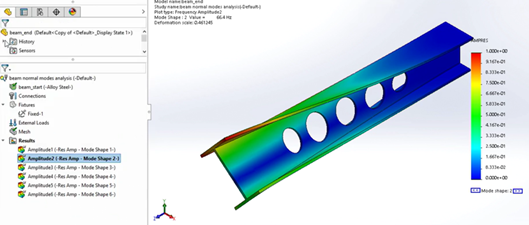

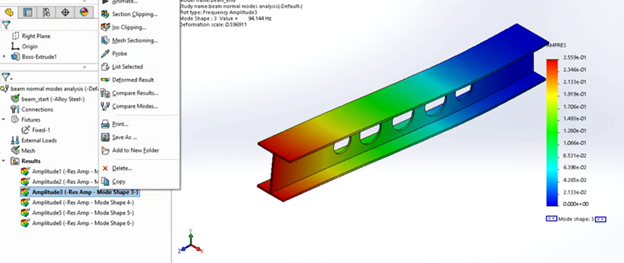

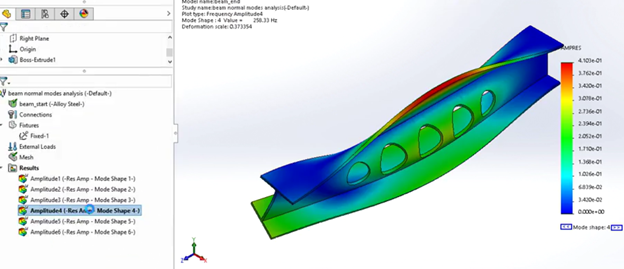

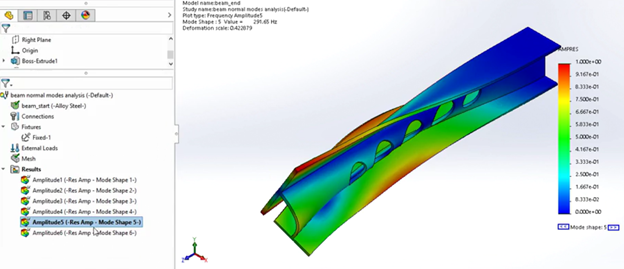

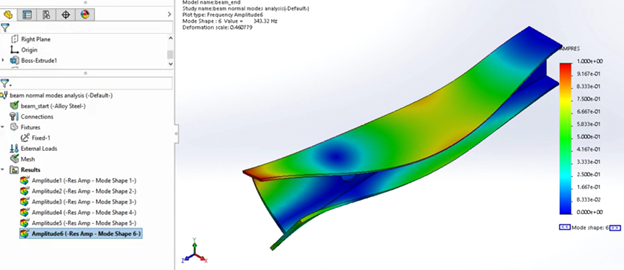

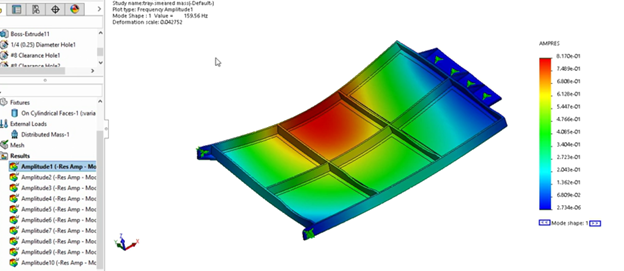

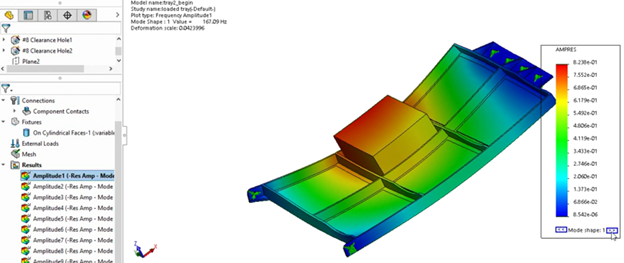

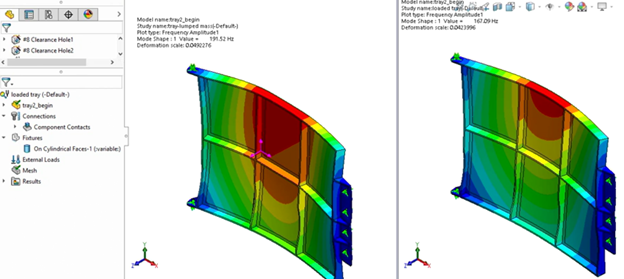

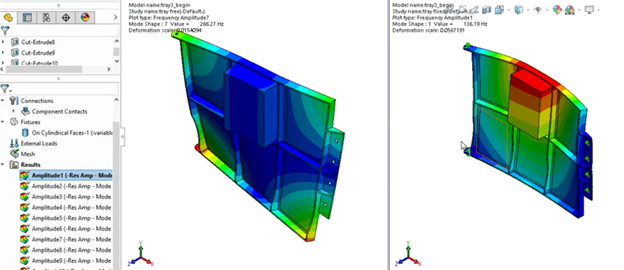

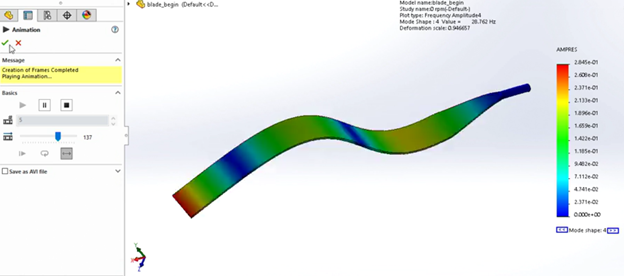

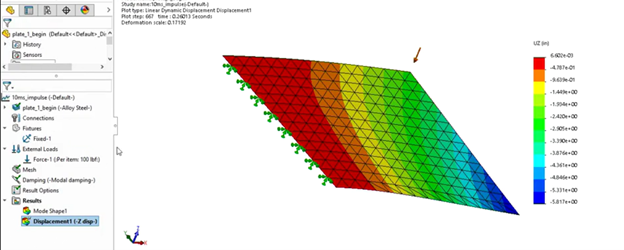

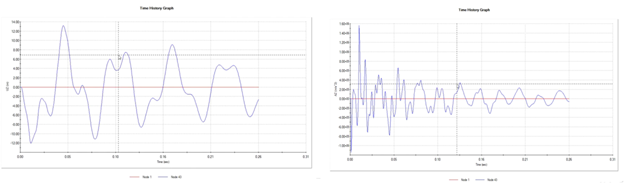

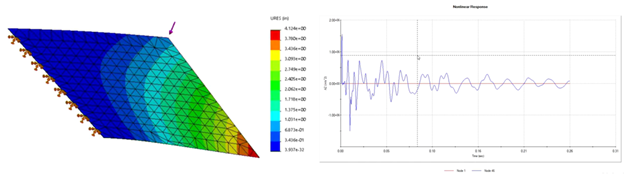

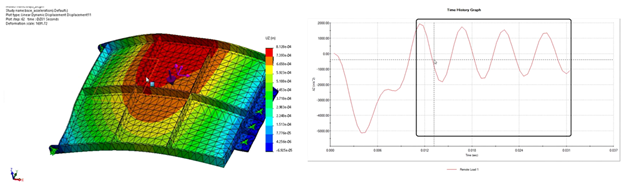

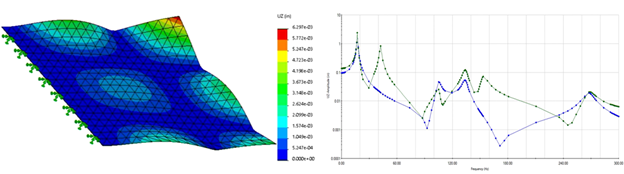

III. DYNAMIC ANALYSIS

Learn how to perform dynamic analysis using SOLIDWORKS Simulation. The course starts by covering dynamics theory and normal modes analysis. Dynamic analysis concepts are covered, including damping, mass participation, modal methods, and direct methods. Next, transient analysis is explored, including modal transient response, direct transient response, and base motion in dynamic response. Then, frequency response analysis, followed by how to interpret results.

Learning Objectives

- Analysis of normal modes

- Modeling different types of masses

- Dynamic analysis

- Controlling transient analysis

- Analyzing motion of bases

- Analyzing frequency response

- Interpreting results of analysis